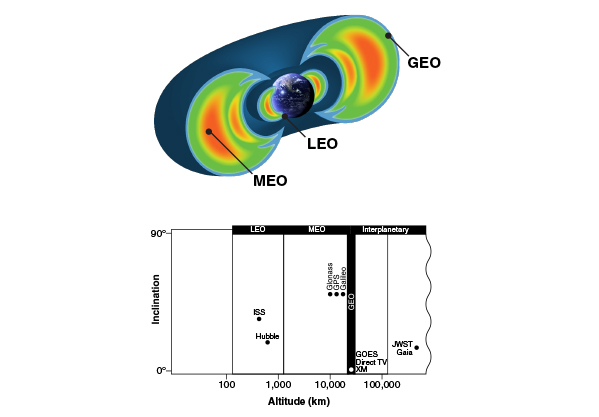

Space Orbits

Low Earth Orbits (LEO) - 200km < LEO < 2000km

Low Earth Orbits pass through the proton and electron particles trapped in the Van Allen belts several times each day.

- Missions using DDC products include ISS, Hubble, Gonets, Proba III, ALOS, GOSAT, Meteor-3, and Pleiades.

Medium Earth Orbits (MEO) 2000km < MEO < 35000km

Medium Earth Orbits pass through the Van Allen belts each day, but also have long exposures to the cosmic ray and solar flare environments regardless of their inclination.

- Missions using DDC products include GPS, Galileo, and Glonass.

Geostationary Earth Orbits (GEOs) and Near-Earth Interplanetary GEO = 35760km, L2 = 1,500,000km

Geostationary Earth Orbits are exposed to galactic cosmic rays and solar flare particles.

- Missions using DDC products include Gaia, JWST, Kepler, Planck, Dawn, Hershel Space Observatory, and Jason.

Interplanetary Missions

Interplanetary Missions are exposed to galactic cosmic rays, solar flare particles, planets, asteroids, and comets.

- Missions using DDC products include Messenger, OSIRIS-REx, Rosetta, Juno, and Mars Curiosity Rover.